![]()

Postal History Introduction

Stampless

Covers

1846

to 1900 Issues

1901-1950

Issues

1951-2003

Issues

Cancels

&

Miscellaneous

Postal

Stationery

Post

Cards

Air

Mail

First

Day &

Event Covers

Parcel Post/Special Delivery

Registered & Official Mail

Commercial & Advertising

Revenue & Postage Due

Wildlife & Game Issues

Complete List of RI Issues

|

Rhode Island Stampless

Covers & Letters |

|||||||||||||||

|

|||||||||||||||

|

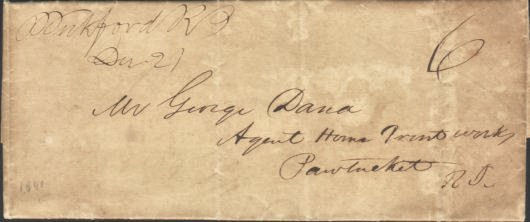

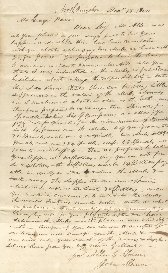

The Stampless Folded Letter

shown above and to the left was sent by John Slocum

acting for Allen Slocum and posted at Wickford, Rhode Island. It was sent

to George Dana, the agent for Horns Print Works

in Pawtucket. The letter was charged at the single

sheet rate of 6 cents Due established by the

Postal Act of April 9, 1816; effective

May 1, 1816 for distances not exceeding

30 miles. There is also a Wickford, RI

script cancellation at the top left of the cover

for December 21st. The letter concerns the

trade or purchase of some Spinning Mules

in exchange for Water Frames and also the purchase

of a Lapper; the difference in spindle count to be

made up in cash. A large percentage of the Rhode Island Stampless Folded Letters from the early to mid 19th centuries deal with cotton and textile mills. The terminology used in the industry tends to be a bit confusing, thus the background information below will explain a few of the terms and relate a little of the history concerning the textile industry along with some of the early innovations used in the manufacture of textiles. The complete text of the letter is appended beneath the history and explanation. |

|||||||||||||||

|

The start of the

Industrial Revolution as it

relates to the textile industry began in

Great Britain

in 1767

where Richard Arkwright

invented and perfected his water frame. The

Water Frame,

(so-called because the frames

used water power to operate)

could spin 128 threads

and did not need a

skilled

operator, whereas the previously invented

Spinning Jenny

could spin a dozen threads,

but needed

a skilled operator.

Arkwright teamed up with

Jedediah Strutt in

1769

and they built their first

water powered factory in

1771

on the Derwent River

in Derbyshire,

England. Samuel Slater,

the father

of the Industrial Revolution

in America learned the

trade when he was apprenticed

to Jedediah Strutt in 1781.

Slater worked

for Jedediah for a period of

8 years and learned the

business from the ground up, eventually

becoming

the Superintendent

of the Mill.

Samuel Slater emigrated to America in 1789 and after being financed by Moses Brown, one of the four Brown Brothers of Providence, Rhode Island, he constructed the first modern spinning mill in Pawtucket. (SEE ALSO: Rhode Island Bicentennial First Day Cover - Slater's Mill History.) Samuel Slater became known as the "Father of the American Industrial Revolution" and Rhode Island became one of the leaders in the textile industry with factories springing up throughout the state, wherever there were rivers that could supply power to the mills. The Slocums are a well known and numerous family in the North Kingstown area and I attended High School with several members of the family. There is even a small village in the area named for the family; "Slocumville." John and Allen Slocum were partners with a Mr. Gardiner, (Slocum & Gardiner) and in 1839 they took over what later became the Hamilton Web Company in 1857 and began spinning cotton and yarns. They operated the mill for 11 years. This letter was written about 18 months after they began operation and appears to be part of their efforts to modernize the mill. |

|||||||||||||||

|

TEXTILE TERMINOLOGY AND DEFINITIONS

Spinning Wheel: an early machine that turned fibers into thread or yarn, which was then woven into cloth on a loom. It was most likely invented in India, reaching Europe during the Middle Ages where it replaced the ancient method of hand spinning the fibers into yarn. Spinning Jenny: Invented by James Hargreaves in 1764, the Jenny was the first practical application of a multiple spinning machine. The original Spinning Jenny used eight spindles instead of the one found on the spinning wheel. A single wheel on the Jenny controlled the eight spindles, which created a weave using eight threads spun from a corresponding set of rovings. Later models had up to one-hundred and twenty spindles. The drawbacks to the Jenny were that it produced a very coarse thread and could not be used on yarns that extended lengthways on the loom, (Warp Threads). It also required a skilled operator to run the machine. Water Frame: A machine invented by Thomas Highs and perfected by the Clockmaker, John Kay for Richard Arkwright. Arkwright is most often given credit for this invention, but in actuality he stole the idea from Highs; he was responsible, however for it's first practical large scale application. The Water Frame was powered by a water wheel and used three sets of rollers, each spinning at a faster speed than the previous, to draw out the cotton roving before the twist was imparted. The thread produced was still course, but the machine's advantage over the Jenny was that it could produce a larger quantity of threads and did not require any skill to operate. Spinning Mule: The Spinning Mule was invented by Samuel Crompton in 1779 and was a combination of the Jenny and the Water Frame. The machine combined the moving carriage of the Jenny with the rollers of the Water Frame and produced a thread, which was both finer and stronger than that produced by the Jenny or Water Frame. The thread that was produced by the Mule is considered by most experts to be of the highest quality and comparable to hand worked yarns. I found two definitions for

Lappers, however I am still not sure which type of

lapper is referred to in the letter. The Complete Text of the Letter follows Below: |

|||||||||||||||

|

|||||||||||||||

RI Historical

Society

Introduction

Stampless I

Stampless II

Stampless III

Stampless IV

Stampless V

Stampless VI

Brown & Ives Letters

The Hazard Family Letters

Joseph Tillinghast

Free Franked Letters

DeWolf Family Letters

Recently Added Pages